Light propagates through hollow optical fiber

Table of Contents

Omnidirectional mirror

Potential advantages

Other applications

Roll the perfect mirror into a tiny tube and what do you get? A hollow optical fiber with increased wavelength real estate, increased power-per-channel, and reduced need for amplification and regeneration compared to conventional fibers. At least, so say the principals of OmniGuide Communications (Cambridge, MA).

This "new" fiber has yet to be fabricated or tested, but the company is building on the theory that employs an omnidirectional mirror developed by Yoel Fink and colleagues from the Massachusetts Institute of Technology (MIT; Cambridge, MA). "At the moment all we have is a theory, but it is an accurate concept on how to guide light," says John Joannopoulos, Francis Wright Davis Professor of Physics Massachusetts Institute of Technology as well as one of the founders of OmniGuide Communications.

Omnidirectional mirror(Back to Top)

Fink's original mirror, constructed as a stack of nine alternating micrometer-thick layers of polystyrene (PS) and tellurium (Te), acted as a dielectric omnidirectional reflector over the wavelength range of 10 to 15 µm. He combined the best properties of existing mirrors—the omnidirectional reflectivity of metallic mirrors together with frequency selectivity and low-loss behavior typical of multi-layer dielectrics. The result:

a perfectly omnidirectional mirror.

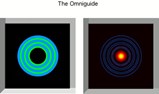

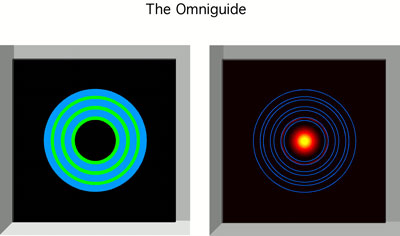

The omnidirectional mirror concept is based on the same principle behind photonic crystals, says Joannopoulos. But unlike photonic crystals, it does not have a complete photonic bandgap. The omnidirectional reflectivity is instead caused by the restricted phase space available to the propagating states of the system (see figure). In other words, the mirror is specifically designed so that light waves propagating from the air cannot couple into modes inside the mirror and consequently are forced to be reflected, he says.

Once the MIT engineers developed this new mirror, Fink suggested "rolling" it into a tube to create an omnidirectional fiber for telecommunications. The details of how the researchers "roll" the mirror are proprietary. "What I can say," says Joannopoulos, "is that this structure will result in new properties for propagating light. And that is the key."

Potential advantages(Back to Top)

These new properties are the main advantages of OmniGuide's proposed fiber over conventional silica glass type, says Uri Kolodny, co-founder and director of marketing at OmniGuide. These properties include the ability to guide light through air and around sharp corners, the possibility of lower losses, higher intensity, and larger bandwidth.

With existing fibers, one cannot send signals greater than several mW per channel, says Kolodny. "Every time someone tries to exceed that, you run into a bunch of non-linear effects that cause signals to mix, raise noise level, etc. We can send powers that are significantly higher per channel," he continues. "We are only restricted by laser sources." Kolodny estimates that the OmniGuide fiber could carry a signal of 1 W or better, producing a 100 times improvement over what exists today.

As to lower losses, Kolodny estimates the OmniGuide fiber can improve today's standards by about 50 times because of the low attenuation associated with moving the light through air. Because the OmniGuide waveguide is designed to have a wider bandwidth, Kolodny estimates the OmniGuide fiber will have an effective available real estate of 600 to 800 nm, compared to 200 nm of conventional fibers.

Other applications(Back to Top)

"Once you have a dielectric mirror that can reflect, no matter what the incoming light's incident angle or polarization, then the applications are extremely broad," says Joannopoulos.

In addition to the fiber, Joannopoulos and associates patented other prospects for their mirror technology. Because it can be "tuned" to reflect certain wavelength ranges and transmit the rest of the spectrum, the substance could be fabricated to appear to be one or many different colors.

One could paint their house with a liquid version of the substance and the film would reflect IR light and be a perfect insulator, while still allowing communication through, says Joannopoulos. Along the same lines, the mirrors could be used in clothing for warmth as well as fashion. OmniGuide engineers are currently working on making the mirror edible, so that it might replace dyes in food. There are also a number of potential medical applications. Fiber optics for telecommunications, however, will be the company's first commercial venture.

The company is gearing up for fabrication. "We've done the computer experiments in our computational laboratory. We know this will work in principle. But now we have to make it work in practice," Joannopoulos says.

OmniGuide Communications expects to have a continuous manufacturing process running within the next 12 to 24 months. "We've found that it is possible to use methods that already exist for pulling fibers," Joannopoulos says. "We will use different materials and different designs, but we won't have to reinvent the process."

When asked if the new fibers will "revolutionize" the industry, Joannopoulos laughs. "There's so much hype in this field, I'd hate to say that. But if we are successful, then that may be true."

About the author…

Laurie Toupin is a freelance writer based in Massachusetts.