White Paper: Cable-Pro supports offshore fiber optic cable handling operations

System overview

Technological improvements

Western Space and Marine has developed a new line of cable handling equipment called Cable-Pro. Cable-Pro can be configured as simple cable haulers or operated with advanced servo controls as linear cable engines. Cable-Pro modules and LCEs also take up less deck space than tire driven units of the same horsepower.

WSM became interested in this technology two years ago when it learned that several users of tracked cable engines were experiencing repetitive and costly failures of roller chain drive mechanisms. Further, operators experience operational problems with control systems that fail to meet expected performance. The company realized that there was solid synergy between the technology that is required to handle cable and WSM's well-established, high-performance manipulator technology. WSM builds heavy-duty industrial systems that have logged more than two million hours in foundry and forge shop applications handling red-hot parts in the worst environments. WSM manufactures remotely operated vehicles for hazardous waste handling and underwater systems for deep ocean applications. Remember the ROV "SNOOP" in Jim Cameron's TITANIC? Been there done that! They also developed the diving helmets and backpacks for Cameron's " THE ABYSS".

The first step was to develop a reliable and robust drive mechanism that is easy to maintain. The engineering staff at WSM, led by Chris Clouser, focused on drive belt technology. At the same time they worked with several experts in rubber compounding to come up with a material that is extremely abrasion resistant and provides excellent mechanical coupling to a wide range of cable sizes and types.

As the new Cable-Pro engines were completed, they were immediately put to work and

completed four months of working sea trials with SAIC/MariPro of Santa Barbara, Calif.

The modules were utilized as general-purpose haulers to load the cable ship Maersk Forwarder and, on a daily basis, to augment the existing linear cable engines during lay operations. The performance of the new belted drive systems proved to be outstanding, with zero drive problems and minor belt wear.

The first systems were implemented with manual controls to qualify the drive mechanism and belt performance. However, WSM's established expertise is in advanced servo control systems as used on Man-Mate, a heavy-duty, industrial manipulator system, and The Arm, a deep-ocean manipulator system. These bilateral control systems provide the operator with force reflection and precision positioning capability. Dynamic compliance allows the systems to react to external forces and protect the mechanical systems and product from inadvertent damage. It is this technology base that forms the core of the Cable-Pro control system as implemented on the Linear Cable Engine that is configured with as many modules as needed to provide system load capacity.

From the onset of the project, several objectives were established to satisfy customer requirements. It was necessary to keep the mechanical design simple, innovative, and robust in order to assure ease of maintenance and long component life. The development team focused on solutions to known problems and concentrated on enhancing performance in areas where new technology measurably improves reliability, maintenance, and performance.

Control technology developed for WSM force reflecting material handling systems is applied to provide a mix of practical designs and proven technology with new ideas to produce a superior system. System sensors are integrated with the latest programmable logic controllers, imbedded processors, and analog signal processors.

The goal was to actively control tension, speed, heave compensation, payout count and accumulation by providing information locally and remotely via serial data links with data organized by file name in a windows environment.

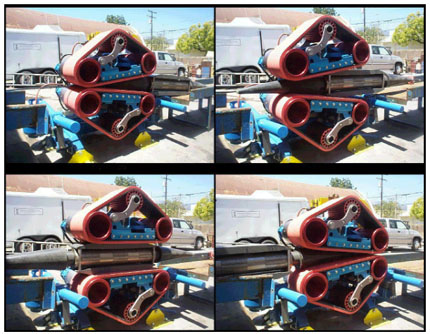

Through research of existing products, an industry-wide need to improve performance and resolve many of the common problems encountered with contemporary systems was identified. The development team was able to make a number of improvements in a modular design. The belt drive is designed to provide long service life. When needed, each belt can be changed in less than 10 minutes, keeping maintenance costs and down time to a minimum. The belt life is estimated to be more than 20,000 km in normal service. The air suspension provides 15 inches of smooth, compliant travel resulting in maximum control over bodies and adjustable squeeze force. The module was designed to pass a large variety of asymmetrical bodies up to 15 inches tall. By using an air cylinder, WSM produced a machine that can delicately pass repeaters at high speed while retaining positive control throughout the duration of the pass.

The following series of pictures illustrate the WSM LCE Module's passing an

11" repeater body.

The Cable-Pro engine features hydraulic motors capable of smooth power transfer down into the inches-per-minute range for greater control while passing bodies, splices, or other problem areas. Optional electric motors are available.

The design team chose universally available parts from manufacturers with global distribution, such as Parker Hydraulics and Pneumatics, Vickers Hydraulics, Allen Bradley, Reliance Electric, Timken and SKF Bearings, to name a few. The engine's open face design provides easy access to internal areas where buildup may occur. Debris removal is accommodated without disassembly. In fact, ease of maintenance was a primary design goal. All grease fittings are easily accessible and all parts are designed for quick removal. For example: the tensioner pulley is changed out by removing retaining clips on its shaft and then sliding out the shaft. A screwdriver is the only tool needed.

Belt drive versus chain link or tire drives The WSM belt drive is designed to have significant advantages over current cable handling drives. Chain link tracks are noisy, allow dirt and cable coatings to enter the mechanism, require excessive change-out time (costly in the yard, much more costly in the field), and work properly in only one direction. Tire drives provide insufficient linear engagement with the cable, require excessive deck space for multiple pairs, and have insufficient width for stability while moving cable and splices.

Cable-Pro belts are much quieter than tracks, keep debris out of the mechanism, change out extremely fast, operate equally well in both directions. They provide better linear engagement with the cable than tracks or tires (32 inches per module), have the width for stability when passing bodies, require minimal linear deck space, and have long belt life.

This photo illustrates how a belt wears after transferring 400 km of 1" armored cable and several dozen 5" splices. The metal bar across the belt helps to illustrate the negligible amount of grooving, which resulted from the job. The grooves are roughly 1/32"-1/16" deep. Belt life could exceed 50,000 km under similar circumstances.

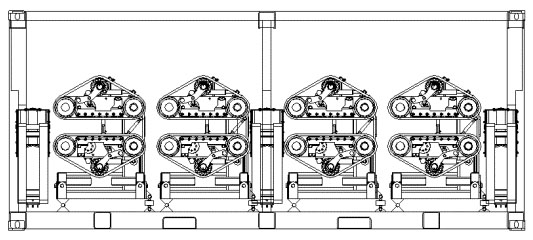

Three Cable-Pro modules are available: one with 1,500 pound pull and four knot speed capabilities, one with 3,000 pound pull and five knot speed capabilities, and one with 6,000 pound pull and six knot speed capabilities. All use the same belt drive mechanism. WSM also offers complete cable engine packages, containerized with operator control booths.

For more information, contact: Western Space and Marine, 111 Santa Barbara St., Santa Barbara, CA 93101. Phone: 805-963-3831, FAX: 805-963-3832. Http://www.wsminc.com